Mid's CAD Program now has one of the best-equipped industrial 3D printing labs in the state.

Through a partnership with Lyseon Additive Manufacturing, Mid's Harrison Technical Education Center is now home to a Stratasys 3D printing lab complete with over $1 million in professional-grade 3D printers and materials.

"Students can now gain the skills and experience needed for high-tech, in-demand careers related to 3D printing right here at Mid - an opportunity they can't find anywhere else."

Leading-Edge Technology

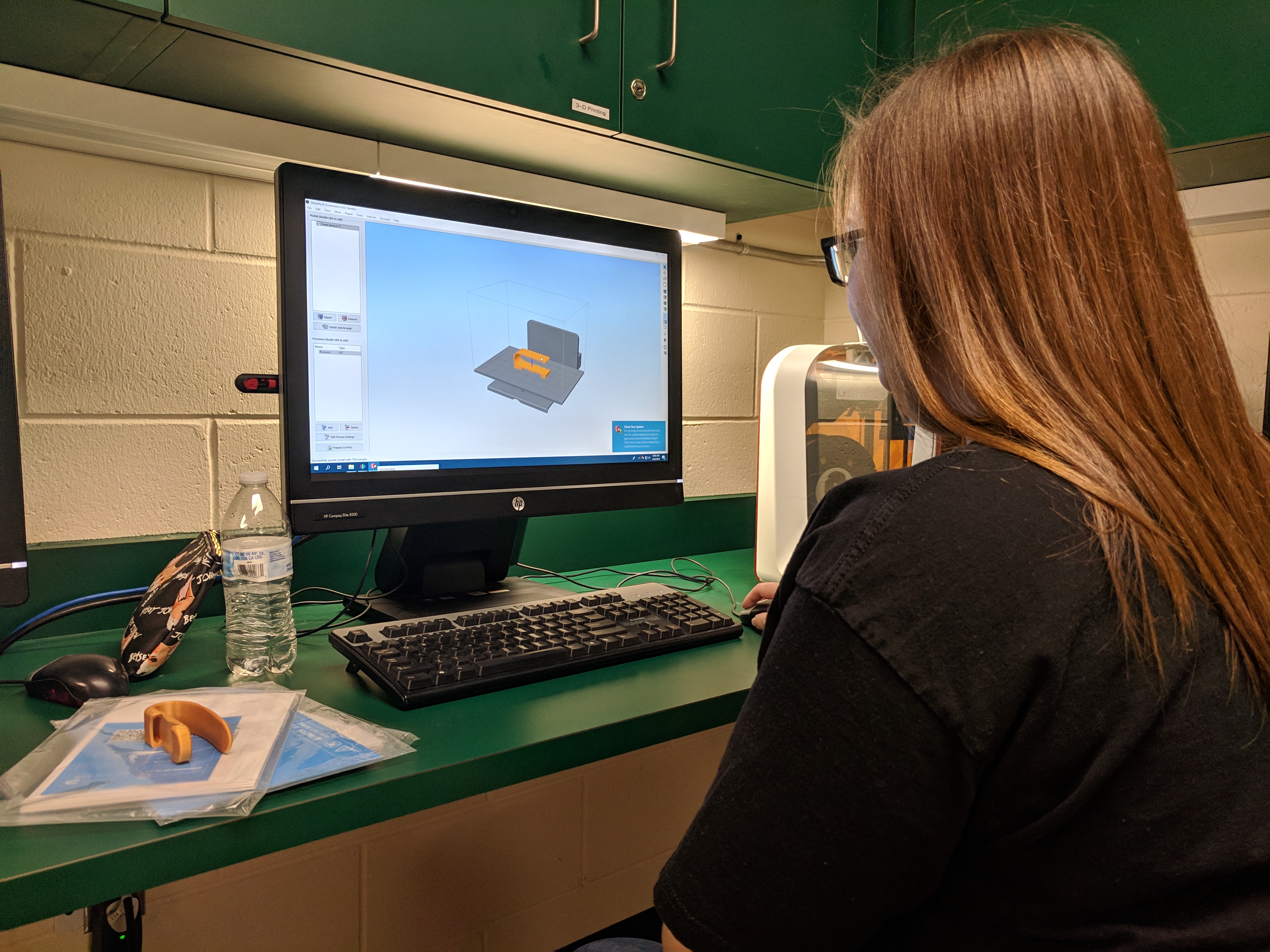

Mid's CAD Program offers courses in three of the most up-to-date, in-demand, industry standard software programs. Graduates can be assured they will be fluent in the following CAD software programs:

- SolidWorks (2D & 3D Mechanical Drafting & Design)

- AutoDesk AutoCAD ( 2D Mechanical Drafting)

- AutoDesk Revit (2D & 3D Drafting & Design)

Each CAD Lab is supplied with 24 computer stations with the latest Windows operating system, as well as the most up-to-date hardware and software as required for running the CAD software programs efficiently.

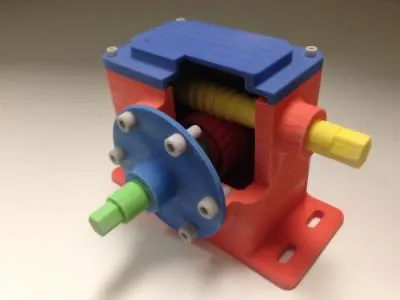

3D Printing & Prototyping

Students in Mid's CADD Program have the opportunity to gain experience with 3D printing and prototyping. At the Harrison Campus Technical Education Center’s 3D Printing Lab we have (8) 3D printers along with some other prototyping and product design equipment/technology. Plans are in place to add a 3D Printing Lab at the Morey Technical Education Center in Mt. Pleasant in the near future.